ZF TraXon gearbox problems on FAW & MAN trucks

Why Mayfair Gearbox should be your first call in South Africa

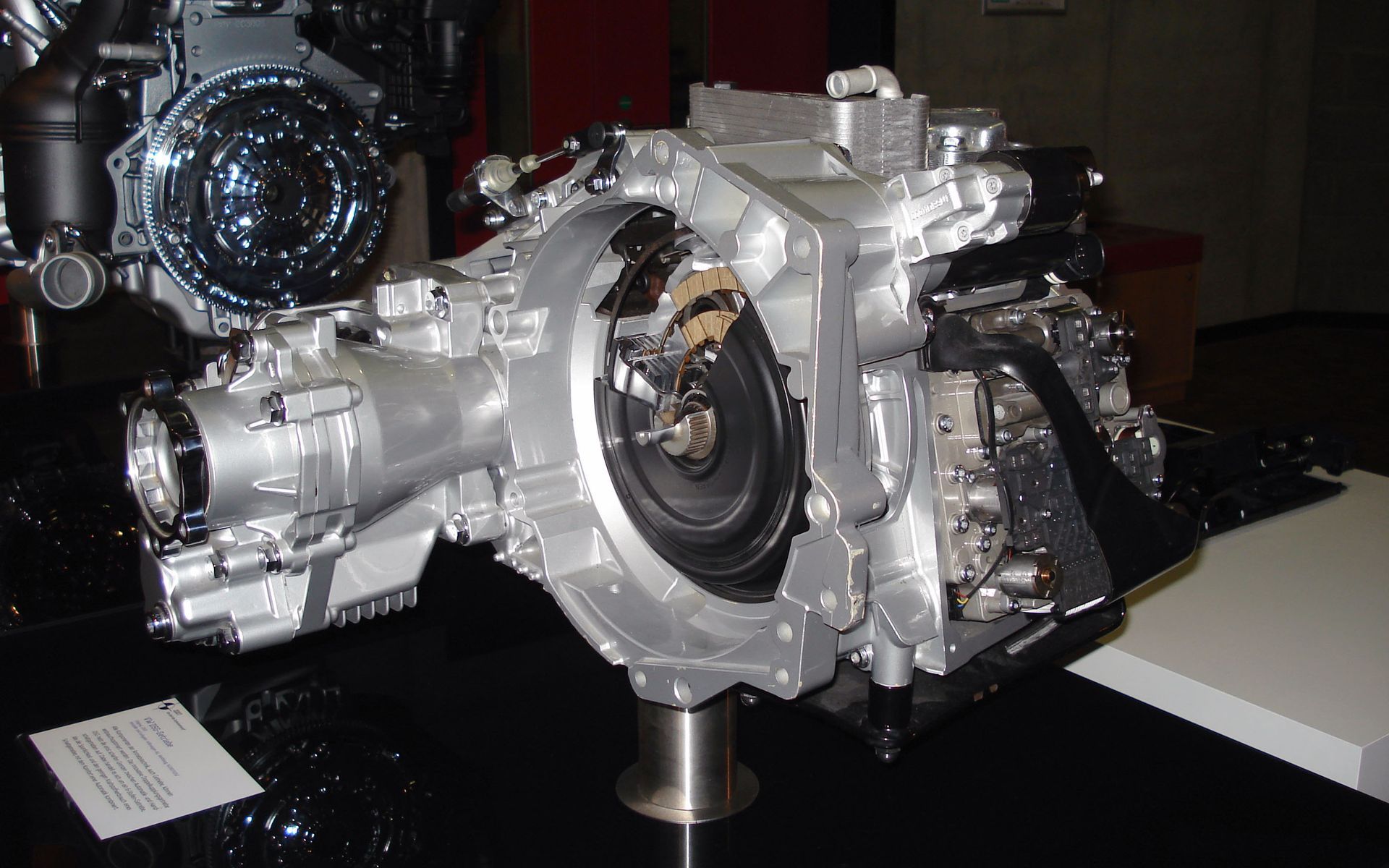

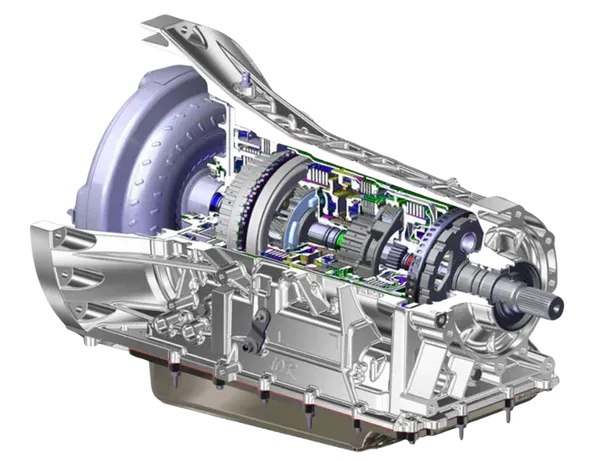

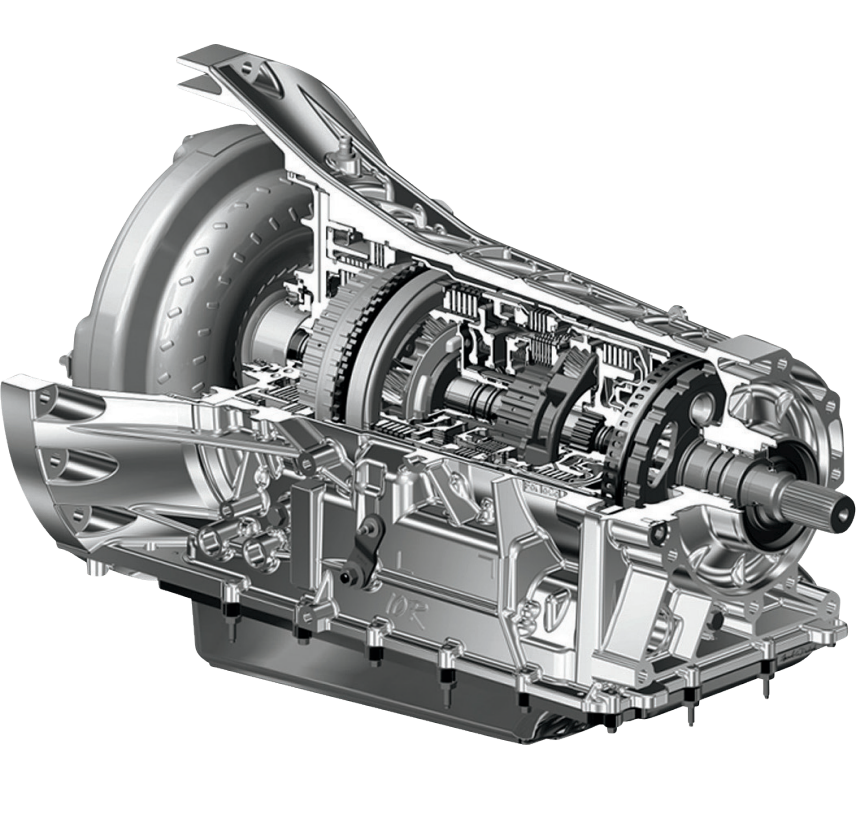

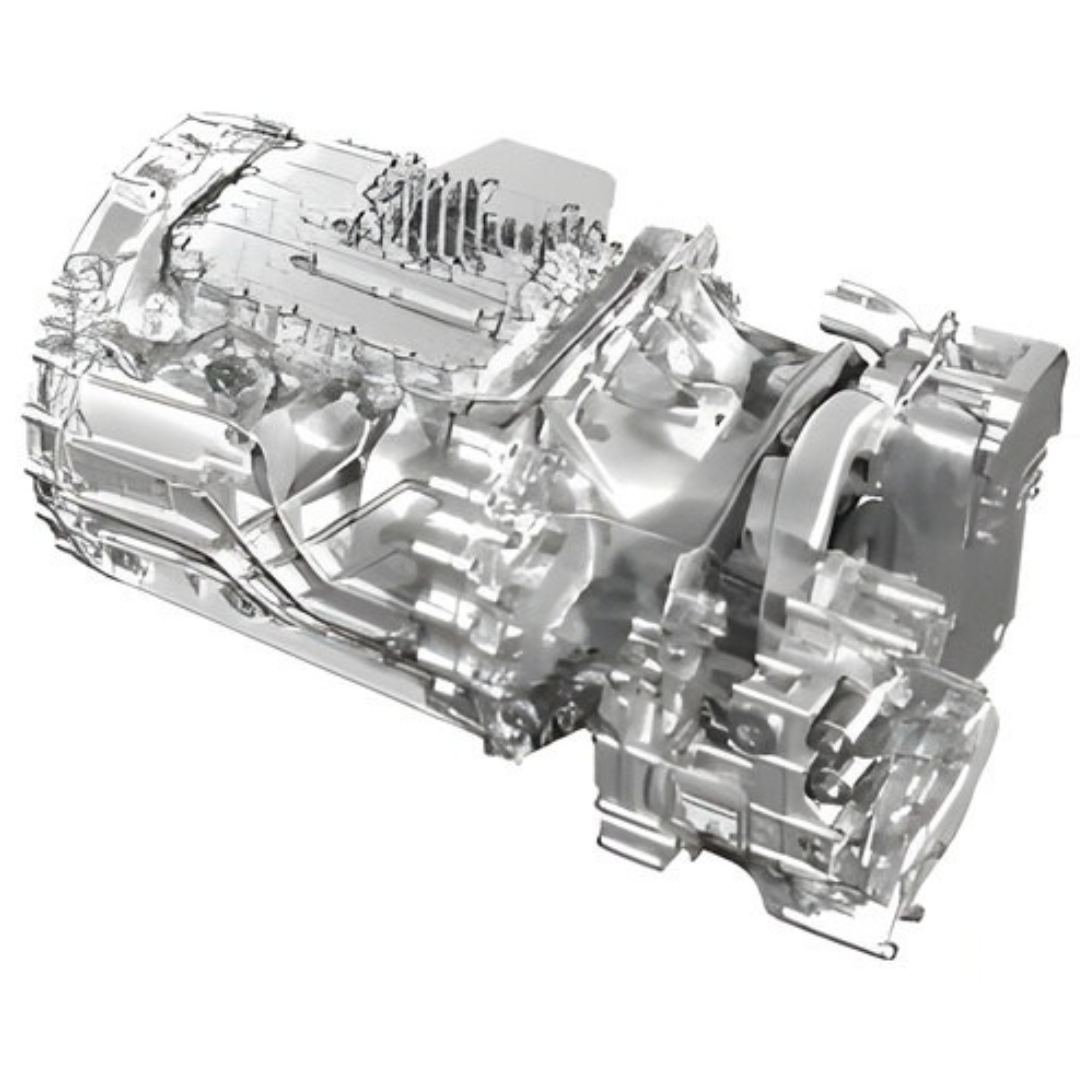

The ZF TraXon is a clever piece of kit – a modular 12- or 16-speed automated manual transmission (AMT) designed for modern heavy trucks. It offers excellent efficiency (up to ±99,7%), high torque capacity (3,000 Nm+), and advanced functions like GPS-based shift strategies and integrated retarders.

In South Africa, you’ll find TraXon boxes in a growing number of fleets, including FAW long-haul tractors and MAN models introduced from around 2017.

When everything is working, they’re smooth and efficient.

When they go wrong, they can become very expensive, very quickly.

This is exactly why Mayfair Gearbox has invested heavily in TraXon capability - so you don’t have to learn the hard way via trial-and-error repairs.

The reality: common ZF TraXon issues we see in South Africa

From what we see in the market (and what global repair facilities report), TraXon failures typically fall into a few categories:

Selector fork & shift rail damage

One of the big headaches is selector fork failure and associated shift rail wear. A few factors usually sit behind this:

Outdated or incorrect software/calibration - Early TraXon units and trucks running old TCU software can suffer from harsh or hesitant shifts. The mechatronic tries to “force” a gear home under less-than-ideal conditions, overloading the fork and synchros over time. TraXon 2 exists for a reason: ZF explicitly highlights improved microprocessors and software to enhance shift quality and durability, which tells you the first generation had room for improvement.

Driver abuse on AMT - “It’s an auto, you can’t break it” is a myth. Riding the throttle, forcing manoeuvres in tight yards, or repeatedly trying to pull away too heavy in the wrong mode hammers the selector hardware. Eventually, forks crack or bend and the box locks in a gear or drops to neutral.

Knock-on damage - Once a selector fork starts to fail, it doesn’t stop there - you often see:

Damaged synchro hubs and sleeves

Chipped dogs

Metal contamination in the oil is attacking bearings and gears

If the fault is ignored, you move from a “selector repair” to a full internal rebuild, with a price tag to match.

Mechatronic / gate selector faults

The TraXon’s brain and muscles - its mechatronic and external gear selector - are another common pain point:

Stuck in neutral / no gear selection - Workshop reports and repair adverts around TraXon show common faults like “gearbox stuck in neutral”, “fails to shift”, CAN communication errors, and “Transmission Fault” warnings on the dash.

Gate selector failures - Specialist diagnostic content specifically calls out gate selector faults, where the selector unit stops giving correct feedback to the TCU, locking the box in a fail-safe gear or neutral until properly diagnosed and repaired.

General ZF selector weaknesses - Across ZF automated gearboxes in general, common selector issues include mechanical wear, electronic failures in the control module/sensors, and dirt contamination blocking the mechanism.

TraXon is no different - if the selector and mechatronics aren’t kept clean, calibrated and updated, you pay for it later.

Software, calibration & fault-code chaos

The TraXon isn’t just cogs and shafts - it’s a tightly integrated software-driven system.

When the logic sees something it doesn’t like, it drops into fail-safe: locked in one gear, stuck in neutral or limp mode.

If you don’t have the right heavy-duty diagnostic tooling and fault trees, you can burn days chasing electrical “ghosts” instead of fixing the root cause.

This is where a lot of “backyard repairs” blow up: parts get thrown at the problem with no clear diagnostic path. Meanwhile, the truck stands, the bill climbs, and the root cause - often software or calibration - is still untouched.

Why TraXon repairs get so expensive

A TraXon box is not a simple synchro manual:

High parts cost - selector forks, synchro hubs, mechatronics, sensors, bearings, and shafts are all premium parts.

Special tools & procedures - the factory disassembly/assembly kits and repair methods are specialised and stringent.

Critical programming and adaptation - even if the hardware is perfect, the gearbox will not behave if software, calibrations and clutch adaptations are not done correctly.

So the question isn’t “who is the cheapest”.

The real question is: who can fix it once, properly, and get my truck earning again fast?

The challenge with going only through the OE route

ZF and the OE dealer network obviously have the deepest factory knowledge – no debate there. But in the real world of South African transport, we see a few practical issues:

- Lead times - the OE route is often tied to global processes, back-orders and central approvals. That can mean long waiting periods while your truck stands.

- Premium pricing - genuine parts, exchange gearboxes and dealer labour are typically priced at a premium level aimed at European markets, not local margin pressure.

- Limited flexibility - OE workshops are not always geared for tailor-made fleet solutions, custom reporting or on-site support at depots.

In simple terms, the OE route is technically strong but not always aligned with the speed and cost pressures of South African haulage.

That’s where Mayfair Gearbox steps in.

Why Mayfair Gearbox should be your first choice for ZF TraXon repairs

1. Deep heavy-duty transmission experience

Mayfair Gearbox has been building its reputation on truck, bus and specialised drivetrain work for decades. We already remanufacture complex units like Ford 6R80/10R80, Voith and other heavy transmissions under strict OEM-level standards.

TraXon is a natural fit for us: high-end, complex, and absolutely unforgiving of guesswork.

2. Specialist TraXon capability - not “we’ll try it”

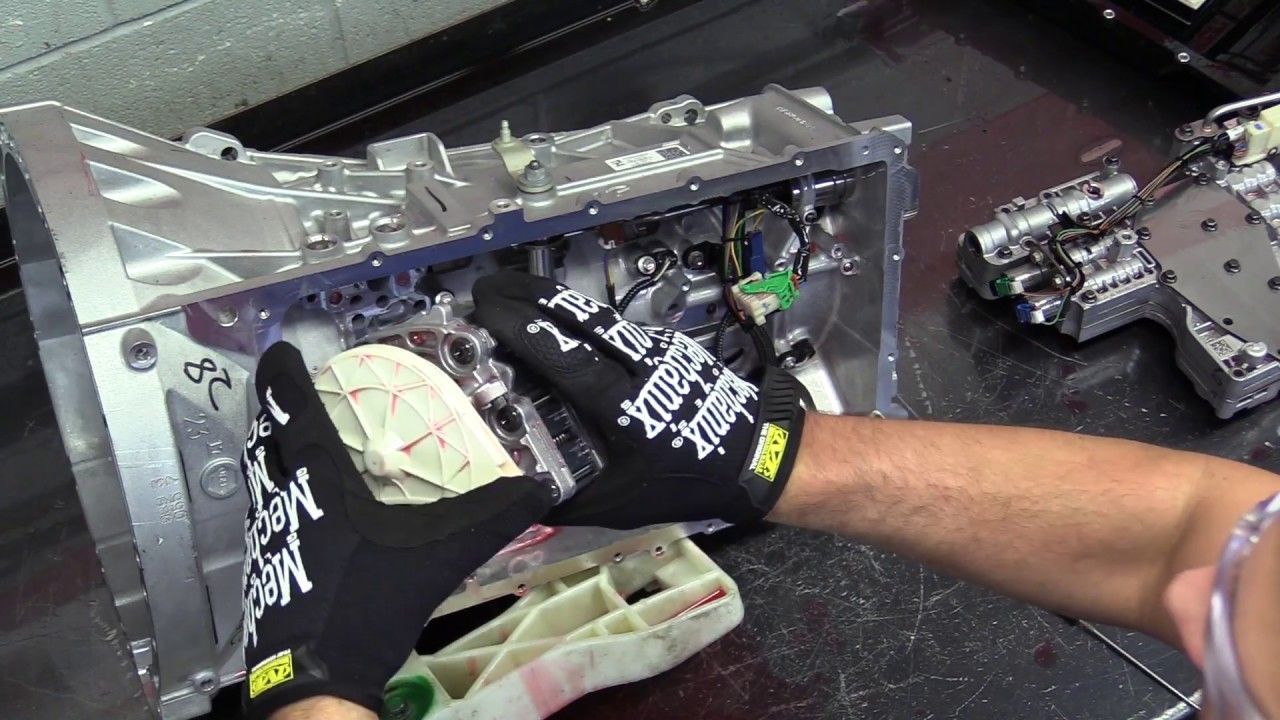

We follow a structured remanufacturing process for TraXon units:

- Proper strip & clean in a dedicated environment

- Detailed measurement of shafts, gears, synchros and forks

- Replacement of high-risk wear parts is standard in our build spec

- Careful inspection of the clutch, flywheel, mounts and cooling system so we don’t refit a gearbox into a sick truck

On top of that, we focus specifically on selector and software-driven failures:

- Upgraded or replaced selector forks and associated hardware where required

- Mechatronic and gate selector testing, repair or replacement

- Correct software updates, coding and adaptations using professional heavy-duty diagnostics and procedures

- Full fault-code root cause analysis before and after repair - no “clear codes and hope for the best”

3. Faster turnaround than the traditional route

Because TraXon is now common in FAW and MAN fleets, we carry:

- Critical TraXon spares in stock

- Built exchange units for fast swap-outs where downtime is critical

This means we can often take you from a dead truck to a running one far quicker than the classic “send away and wait” model.

4. Cost-effective, without cutting corners

We are blunt about this: TraXon will never be a cheap box to fix.

What we can do is:

- Control costs by remanufacturing what is still serviceable instead of blindly replacing entire assemblies

- Use a mix of OEM and carefully selected aftermarket parts where appropriate to balance cost and longevity

- Prevent repeat failures by correcting software, cooling, clutch and operational issues – not just the broken parts

Lower total cost per kilometre, not just a low line-item on one invoice.

5. Every TraXon is tested before it leaves

There is no point building a beautiful gearbox that has never been proven under load.

At Mayfair, TraXon units are end-of-line tested on a dedicated transmission dyno before we sign them off. Shift quality, gear engagement, clutch control and fault-code behaviour are checked and documented so you don’t become our test bench on the highway.

What you should look out for on your FAW or MAN with ZF TraXon

If you run FAW, MAN or any other truck fitted with ZF TraXon and you notice any of the following, don’t ignore it:

- Delayed or harsh shifts, especially under load

- The truck suddenly got stuck in one gear or in neutral

- Gearbox or transmission fault warnings on the dashboard

- Strange “backlash” or banging when changing between drive and coast

- Repeated selector or mechatronic fault codes that “come back” after clearing

These are early warning signs that the selector forks, mechatronics or internal hardware are not happy. Catch it early, and the bill is manageable. Leave it, and you’ll be paying for major internal damage.

Bring your TraXon problems to a team that lives transmissions

ZF TraXon is brilliant technology - but like all advanced systems, it demands specialist handling.

- If you’re tired of long lead times and premium pricing on TraXon gearbox repairs

- If you’ve already replaced mechatronics and still fight the same fault codes

- Or if you simply want a reliable, tested, cost-effective solution for your FAW or MAN fleet in South Africa

Talk to Mayfair Gearbox first

We understand

TraXon from the inside out - mechanically, electronically and in software - and we’re geared to keep your trucks doing what they’re built to do: pull loads and make money, not sit over a pit waiting for parts.