How a VW DSG Mechatronic Works (and why a proper reman matters)

Short answer: the DSG’s mechatronic is the brain and muscle of the gearbox. It reads what the car and driver are doing, makes split-second decisions, and then moves clutches and gear selectors hydraulically/electrically to deliver seamless shifts. If it’s weak, the whole car feels wrong. If it’s right, you get lightning-quick, repeatable performance with OEM drivability. Below is a clear, no-nonsense breakdown you can use to diagnose, explain to customers, and make the right repair decisions.

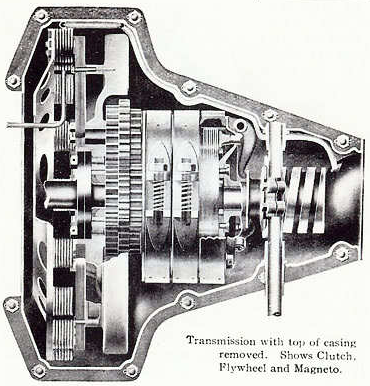

DSG refresher: what the box is doing

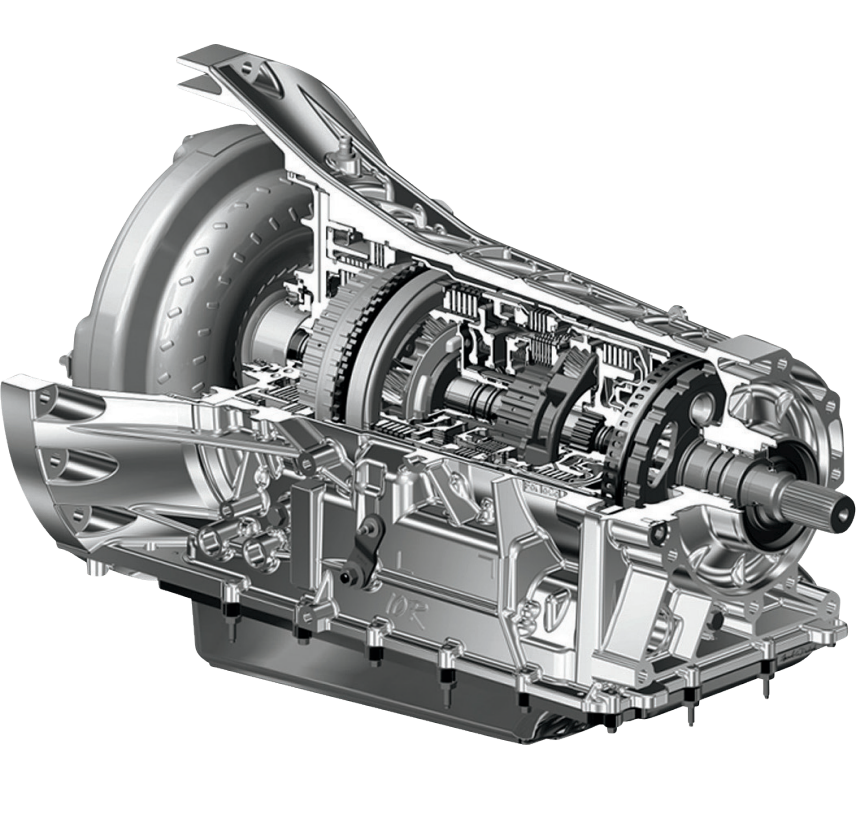

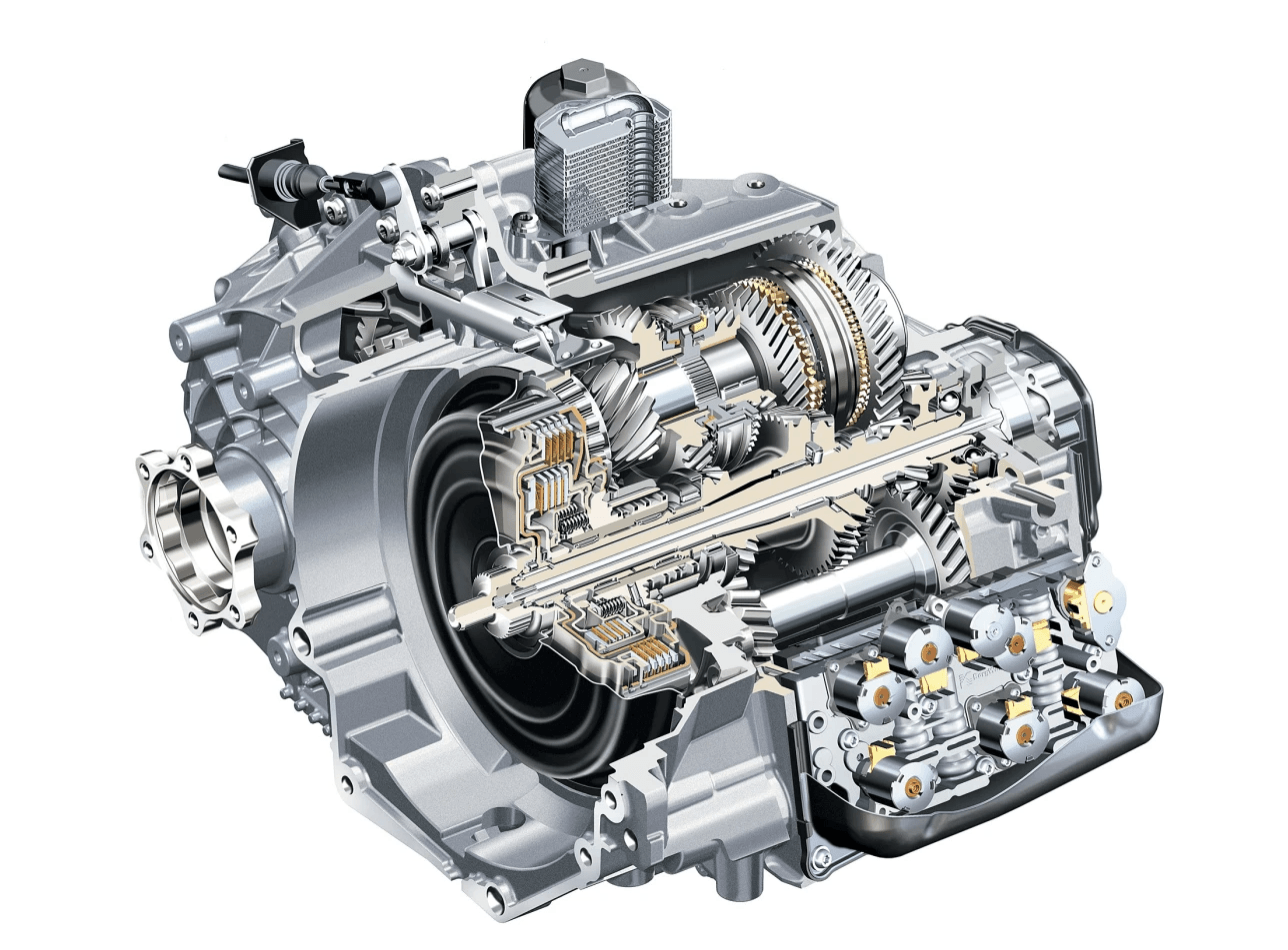

Volkswagen Group’s DSG (Direct-Shift Gearbox) is a dual-clutch transmission. One clutch handles the odd gears (1/3/5/7), the other handles the even gears (2/4/6/R). While you’re accelerating in one gear, the next gear is already pre-selected. When the mechatronic swaps clutches, you get an almost uninterrupted flow of torque.

Common variants in our market:

- DQ200 (0AM/0CW) - 7-speed, dry clutch, used on smaller engines.

- DQ250 (02E) - 6-speed, wet clutch, very common (VW, Audi, Skoda, Seat).

- DQ381/DQ380 - 7-speed, wet clutch, newer MQB platform.

- DQ500 (0BH/0DL) - 7-speed, heavy-duty wet clutch (SUVs, vans, performance).

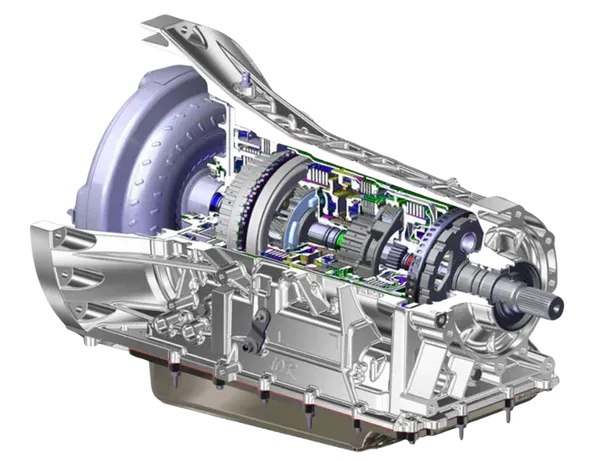

What exactly is the “mechatronic”?

It’s a compact module that combines electronics (TCU), hydraulics (valve body + pump/accumulator) and sensors/actuators into one serviceable unit. Think of it as:

1. TCU/ECU (the brain)

- Runs the shift and clutch algorithms.

- Talks to engine ECU, ABS/ESP, and instrument cluster.

- Stores fault codes and adaptation values.

2. Hydraulic power & distribution (the muscle)

- Electric hydraulic pump builds system pressure.

- Accumulator smooths pressure spikes and supplies quick bursts for fast shifts.

- Solenoid valves route pressure to:

- Clutch control circuits (apply/release K1 and K2)

- Shift actuators (select & engage gear trains)

- Precision spools/bores meter oil like a carburettor jet-microns matter.

3. Sensors (the senses)

- Pressure sensors (main line & clutch circuits)

- Temperature (fluid strategy & protection)

- Speed/position sensors (input/output speeds, selector positions)

- Feed real-time data back to the TCU for closed-loop control.

Result: The mechatronic balances clutch torque capacity, shaft speeds, and engine torque requests to deliver the gear you want without slip, shudder, or lag.

How a shift actually happens (simplified)

- Predict - TCU reads throttle, brake, speed, gradient, and drive mode.

- Pre-select - Next gear is lined up on the idle clutch side.

- Synchronise - TCU matches target shaft speeds by trimming torque and modulating pressure.

- Swap clutches - One clutch ramps off while the other ramps on, in milliseconds.

- Adapt - Wear and tolerances are learned; TCU updates kiss-point, fill times, and pressure maps.

If any part of that loop is off, pressure weak, valve sticky, sensor noisy, you’ll feel flare, bang, slip, or hesitation.

Typical DSG mechatronic failure modes (what we actually see)

- Pressure loss/pump or accumulator failure

- Long priming times, “pressure too low” faults, neutral-like events when hot.

- Leaking bridge seals & cracked separators

- Cross-leaks cause clutch control drift, odd/even side imbalances, and overheat warnings.

- Sticky or worn solenoid/valve bores

- Harsh 2-1 or 3-2, delayed engagement D/R, random N on coast-down.

- Sensor drift or failure (pressure/temperature/position)

- Intermittent limp, inconsistent clutch bite, adaptation won’t complete.

- TCU electronics faults

- Communication errors, no-start (selector not recognised), permanent limp mode.

- DQ200 specifics (dry clutch)

- Thermal stress and contamination are common; pump relay and accumulator cracks show up often.

- DQ250/DQ381/DQ500 specifics (wet clutch)

- Sheared clutch debris and varnish block fine passages; overheat from towing/performance mods.

Driver complaints that line up with the above:

- Jerks when selecting D/R, rolling stop “thud,” shudder pulling away, delayed take-off, random N, hot-only problems, or an adaptation that refuses to complete.

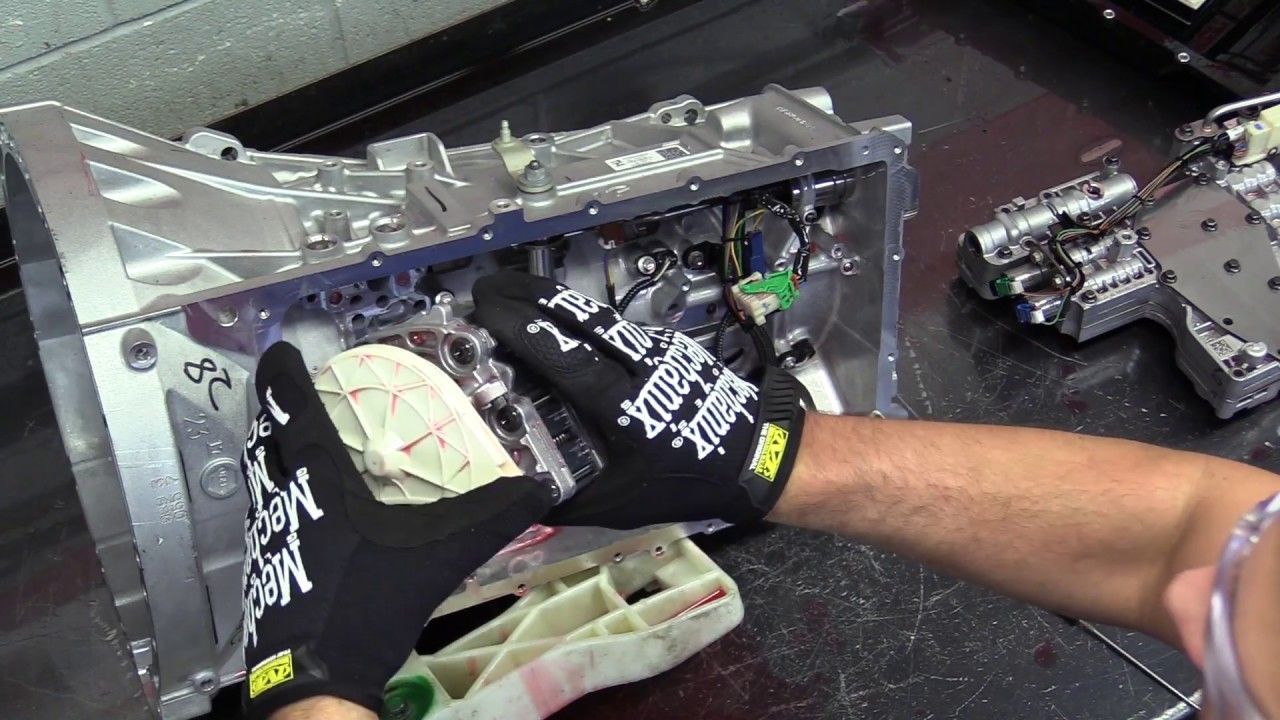

What proper diagnosis looks like (no guesswork)

1. Scan with live data & freeze-frame

- Look at line pressure, clutch pressure commands vs actual, pump duty cycle, temp, and learned values.

2. Hydraulic integrity tests

- Pressure decay, hold tests, and leak-down to isolate internal cross-leaks.

3. Electrical tests

- Solenoid resistances, current ramps, actuator sweeps, TCU supply/grounds, and CAN integrity.

4. Mechanical inspection

- Separator plates, bridge seals, spool wear, debris patterns (tell you where it’s failing).

5. Controlled road test

- Reproduce hot conditions; log shift timings, flare %, clutch slip RPM, and torque truncation.

6. Adaptations & software

- Baseline and post-repair adaptations (basic settings), check for calibrations/updates that improve control logic.

If a workshop is skipping steps 2–6, they’re guessing.

Repair vs replace: the business case

- New OEM mechatronic: expensive, sometimes on back order, and still needs adaptation.

- Used unit: unknown history; may carry the same wear in a different box-false economy.

- Remanufactured: smartest TCO. You fix the root cause, update weak points, and return a unit with measured performance.

What a high-quality reman should include:

- Precision-measured valve bores; reamed/sleeved where needed.

- New seals, bridge plates, gaskets, and updated accumulators where applicable.

- New or graded-to-spec solenoids with matched flow rates.

- Pump/pressure control confirmed on a calibrated bench.

- Clean-room assembly; particle counts kept to spec.

- TCU tested, repaired where necessary, and pre-configured.

- Full hot/cold test cycle with shift-timing and leakage reports.

- On-car basic settings/adaptations with verified clutch kiss-points.

Preventative advice that actually helps

- Fluid matters (wet DSG): correct spec, correct level, correct change interval-especially if towing or tuned.

- Cooling: watch temps on mountain passes or track-day abuse; heat kills hydraulics and electronics.

- Software adaptations: after clutch or mechatronic work, always run basic settings; skipping this shortens life.

- Clean power: weak batteries and voltage dips create ghost faults and solenoid misfires.

Quick FAQ

- What is a DSG mechatronic? The combined TCU + valve body + pump + sensors module that controls clutches and gear changes.

- Symptoms of a failing mechatronic? Jerks, delayed D/R engagement, hot-only neutral events, shift flare/bang, limp mode.

- Can a DSG mechatronic be repaired? Yes, properly remanufactured units routinely outperform aged OEM units.

- How long does it take? With stock and a professional workflow, a 48-hour turnaround is realistic.

- Is reman as good as new? If built and tested to spec with updated parts, often equal or better than new for durability and cost.

Why Mayfair Gearbox is the smart choice in South Africa

When your livelihood depends on uptime and drivability, you don’t want experiments-you want a repeatable result.

Our promise, backed by process:

- Depth of experience: Our DSG benches, fixtures, and adaptation procedures have been refined across DQ200, DQ250, DQ381, and DQ500 programmes on thousands of South African vehicles (VW, Audi, Skoda, Seat).

- True reman-not a rinse and reseal: We correct root causes-bore wear, cross-leaks, accumulator weaknesses, solenoid flow variance, and TCU faults-using upgraded components and calibrated test rigs.

- Measured performance: Every mechatronic leaves with pressure, leakage, and shift-timing reports, and we complete on-car basic settings/adaptations so you don’t chase your tail.

- Turnaround that respects downtime: Two-day turnaround on most DSG mechatronics with exchange stock on hand.

- Value you can defend: Our reman mechatronics are as good as, or better than, new, typically at around half the cost of a new unit, with a 1-year warranty for peace of mind.

Bottom line: If your VW/Audi/Skoda/Seat DSG mechatronic is slipping, banging, hunting, or throwing pressure faults, Mayfair Gearbox will return it to OEM-grade operation, quickly, predictably, and cost-effectively.

Book your assessment: Call Mayfair Gearbox JOBURG OR PRETORIA BRANCH or message us to schedule a same-day diagnostic and get your DSG shifting perfectly again.